The Physics Problem: When Intelligence Leaves the Screen

For the last two decades, we have been trapped behind the glass.

We have built magnificent cathedrals of logic, towering systems of data, and optimized engines of commerce; all confined within the safety of the screen. We optimized the pixel. We reduced the latency of information transfer. We built Large Language Models that can recite poetry and write code, but they remain fundamentally ghostly. They exist in a vacuum, decoupled from the unforgiving laws of physics.

In the digital realm, a mistake is a bug. It can be patched. The cost of failure is virtually zero; a flickering pixel, a server restart.

In the physical world, a mistake is a collision. It is broken metal, wasted fuel, and severed limbs. The cost of failure is absolute.

We are now crossing the Kinetic Threshold. Intelligence is migrating from the abstraction of the cloud into the execution layer of the concrete world. We are moving from AI that describes the world to AI that navigates it.

This shift; Physical AI; is not about humanoid robots performing backflips for viral clips. That is vanity. That is hype.

The reality is structural. It is the integration of high-fidelity World Models into industrial logic. It is the transition from automated scripts to autonomous systems that understand gravity, friction, and mass before they ever engage a motor.

This is the final death of the hero. It is the birth of the machine that manages the physical load.

I. The World Model: Simulating Gravity

Current AI operates on probability. An LLM predicts the next token based on statistical likelihood. It doesn’t “know” what a sentence is; it knows what a sentence looks like.

Physical AI cannot operate on probability alone. It requires causality.

If a robotic arm attempts to lift a crate, it cannot hallucinate the weight. If a logistics drone navigates a warehouse, it cannot guess the coefficient of friction on the floor. It must understand the immutable laws that govern the space.

This is where World Models enter the architecture.

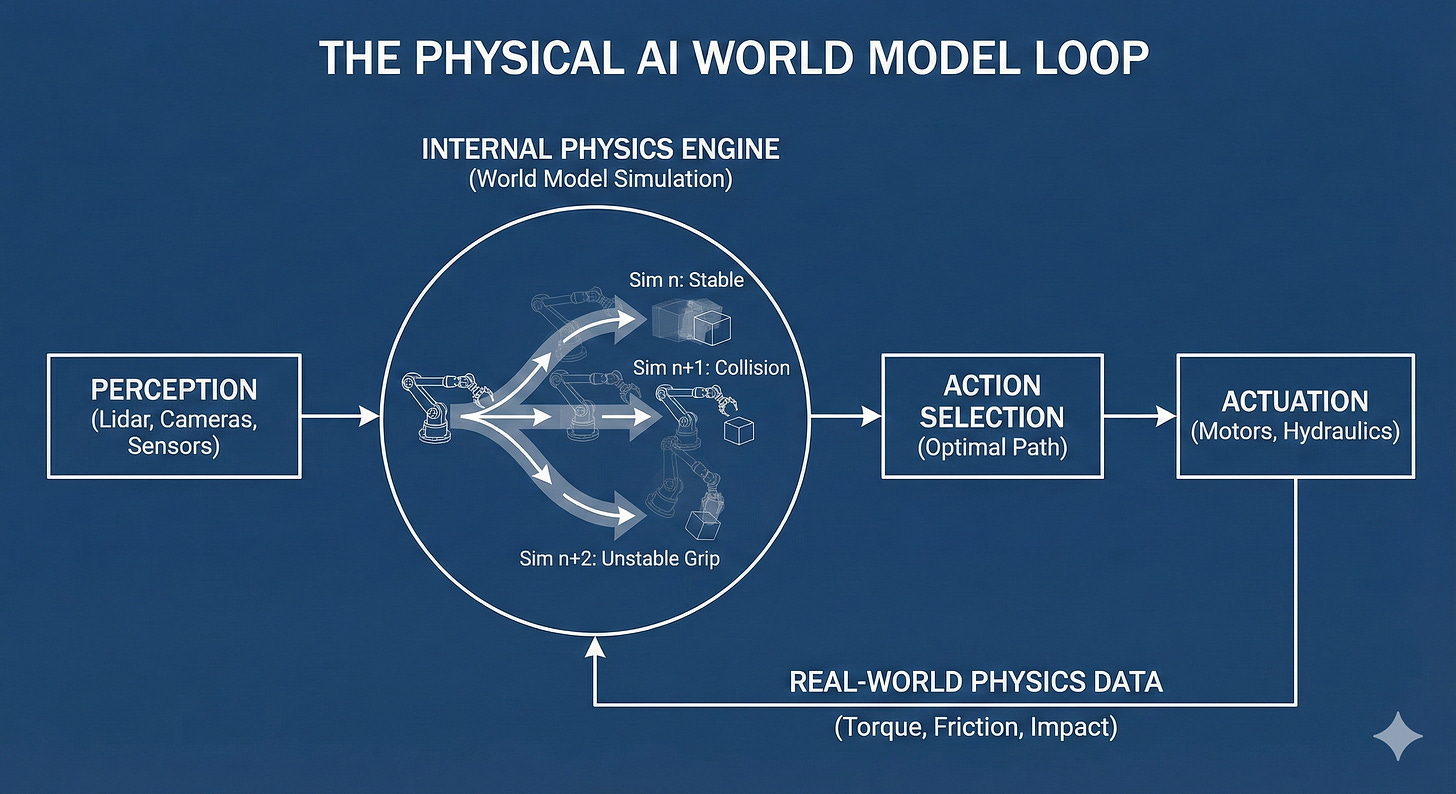

A World Model is not a database. It is a physics engine for intelligence. It allows the system to run internal simulations of the future—thousands of potential kinetic outcomes—before committing to a single action in reality. It is the machine equivalent of “imagination,” but constrained by Newtonian mechanics rather than creative whims.

Consider the human operator. When a veteran machinist looks at a piece of steel, they don’t just see a shape. They intuitively understand its density, its thermal properties, and how it will react to the cutter. They have a “gut feeling” born of experience. That gut feeling is a biological World Model, trained over decades of trial and error.

Physical AI digitizes this intuition. It creates a synthetic understanding of cause and effect.

This changes the fundamental nature of automation. Old automation was blind repetition: Move to X, Grip, Move to Y. If the box was slightly misaligned, the machine failed. It had no concept of “misalignment”—only coordinates.

New automation is adaptive. It perceives the misalignment, simulates the physics of a corrected grip, predicts the torque required to compensate, and executes the adjusted path in real-time. It doesn’t just follow instructions; it solves physical problems.

The screen was the training ground. The factory floor is the exam.

II. The Execution Layer: Scaling Kinetic Action

We have spent years obsessing over the “Application Layer” of software—the interfaces, the dashboards, the user experience. We ignored the “Execution Layer”—the point where code translates into kinetic energy.

Scaling software is easy. You copy the code. You spin up a new server instance. The marginal cost of reproduction is zero.

Scaling physical operations is excruciating. It fights you. You cannot copy-paste a factory. You cannot spin up a new logistics fleet with an API call. Physical scaling encounters resistance: gravity, entropy, and the limitations of human biology.

Physical AI attacks this resistance by decoupling intelligence from biological limits.

Until now, complex physical tasks required a human in the loop. A human had to drive the forklift. A human had to inspect the weld. A human had to pack the truck. The human was the “hero”—the universal adapter that bridged the gap between rigid machines and a chaotic world.

But the human is also the bottleneck. The human gets tired. The human has a limited bandwidth for attention. The human breaks under load.

When we inject intelligence into the Execution Layer, we remove the need for the biological bridge. The system becomes capable of handling the variance of the real world directly.

This is not just about replacing labor; it is about changing the architecture of production.

Imagine a supply chain that acts like a liquid. Autonomous trucks don’t just drive; they coordinate as a swarm, adjusting routes dynamically based on a World Model that predicts traffic density and fuel consumption with physics-level precision. Warehouses where arms don’t just pick and place, but pack with a structural understanding of load distribution, maximizing density and stability without human oversight.

The system stops reacting to chaos and starts managing it.

III. The Friction of Reality

The digital world is frictionless. Data moves at the speed of light.

The physical world is defined by friction. Everything degrades. Everything resists movement. Entropy is the default state.

Traditional automation tried to eliminate friction by controlling the environment. We built cages around robots. We bolted them to the floor. We made the environment predictable so the dumb machine wouldn’t fail. We tailored the world to fit the machine.

Physical AI inverts this dynamic. It tailors the machine to fit the world.

With advanced World Models, a machine can operate in an unstructured environment. It can navigate a construction site, which is a landscape of constant change and hazard. It can handle a warped pallet. It can adjust to a slippery floor.

This ability to handle “edge cases” in the physical realm is the holy grail.

In software, an edge case throws an error. In the physical world, an edge case causes an accident. By embedding a physics-compliant understanding of the world into the AI, we drastically widen the operational envelope. The machine no longer needs a perfect environment. It can operate in the messy, dirty, unpredictable reality that humans inhabit.

This is where the “Quiet Heavyweight” perspective is essential. We must reject the sensationalism of the “all-knowing AI.” These systems do not need to be conscious. They do not need to write poetry. They simply need to be structurally sound.

They need to respect the gravity of the situation—literally.

The “Quiet Middle” of this revolution is not in the flashy demos of robots dancing. It is in the dull, repetitive, dangerous tasks that currently require human cognition only because machines were too stupid to understand friction.

It is the visual inspection of infrastructure—drones that understand the structural integrity of a bridge, not just by image recognition, but by analyzing stress loads in their World Model. It is the agricultural bot that understands the delicate pressure required to pick a strawberry versus the force needed to pull a weed.

This is competence. This is the elimination of drift.

IV. The Flatland Fallacy: Why Code Hits a Wall

We are witnessing a collision between two tribes that have historically ignored each other: the Software Engineers and the Mechanical Engineers.

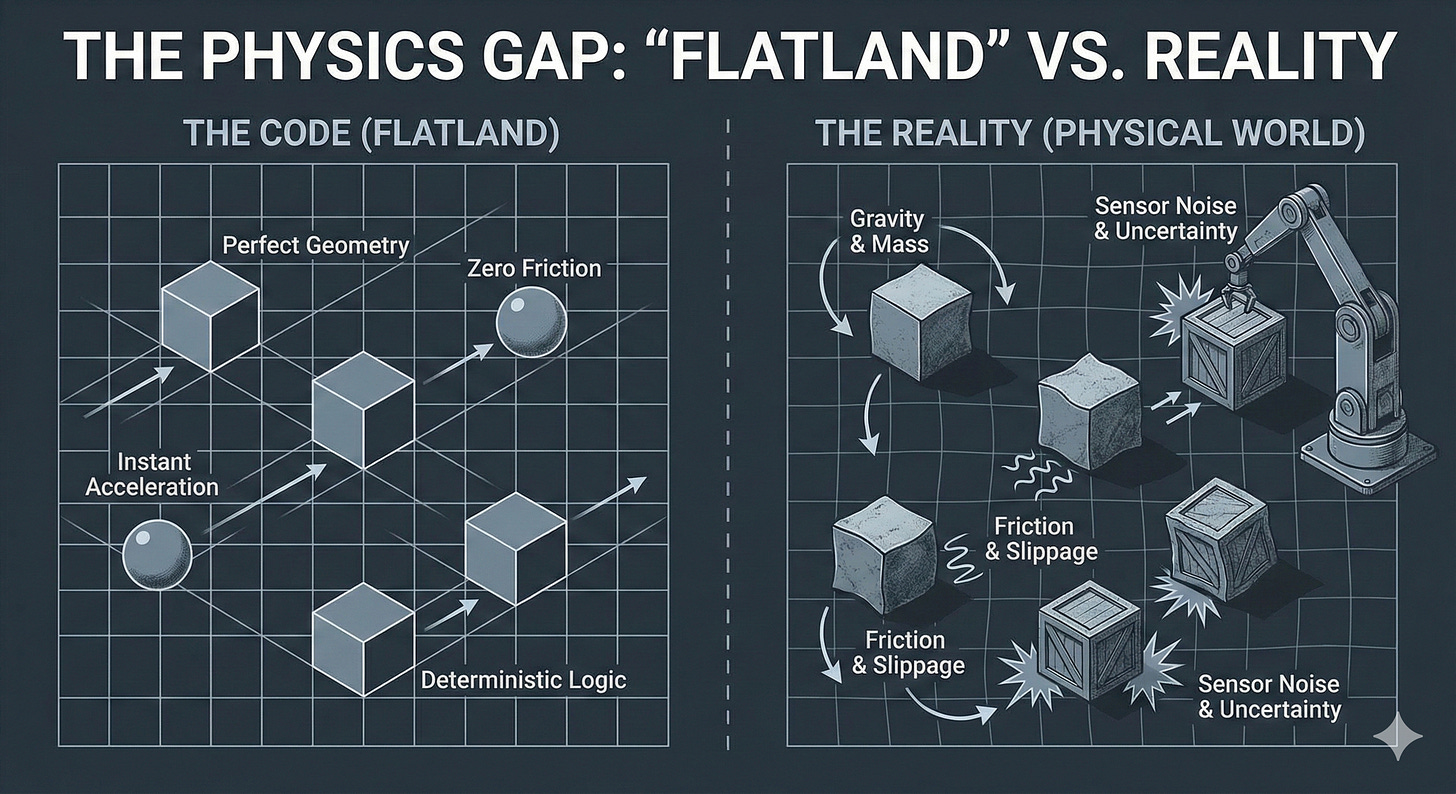

The average software engineer lives in “Flatland.” They inhabit a two-dimensional universe of logic gates and pixels. In their world, gravity does not exist. Inertia is a foreign concept. If they write a loop that runs a million times, the only penalty is heat and time.

This creates a Physics Gap.

Traditional software engineering is built on the illusion of perfect control. You define a variable; it holds the value. You send a packet; it arrives (or you retry). It is a deterministic, discrete environment.

The physical world is continuous, chaotic, and unforgiving. It is defined by hysteresis—the dependence of the state of a system on its history. A motor doesn’t just “turn on”; it draws current, overcomes static friction, heats up, and experiences torque ripple.

When a SaaS engineer tries to code for a robot, they treat the physical actuator like an API endpoint. They send a POST /move request. They expect the arm to teleport.

They fail to account for the mass of the arm. They fail to account for the momentum that must be arrested. They fail to realize that stopping a physical object requires energy dissipation, not just a break statement.

This is not a lack of intelligence; it is a lack of dimensional context. We have spent twenty years training engineers to optimize for Big O notation, not F=ma. We prioritized latency over load-bearing capacity.

To bridge this, we need engineers who understand that code has weight. Every line of logic in a physical system exerts a force. If you don’t calculate the counter-force, something breaks.

V. The Gamer’s Dilemma: Simulation vs. Consequence

There is one group of “software” people who do understand 3D space, vectors, and collision detection: Game Developers.

Designers and developers raised on Unity and Unreal Engine possess a native fluency in spatial logic. They think in quaternions. They understand ray-casting. They have spent their careers simulating gravity, lighting, and rigid body dynamics.

Theoretically, they are the perfect recruits for the Physical AI revolution.

But there is a structural mismatch. The “Operating System” of the industrial world—the PLC (Programmable Logic Controller), the SCADA systems, the archaic proprietary languages of robotic arms—was not built for them. It is hostile territory.

Industrial systems are rigid, low-level, and obsessed with safety-critical timing (microseconds). Game engines are built for “good enough” physics. In a video game, if a character’s arm clips through a wall (ragdoll physics glitch), it’s a meme. In a factory, if a robotic arm clips through a safety cage, it’s a lawsuit and a funeral.

We have a talent pool ready to build the future, locked out by the tools of the past.

The current industrial stack is high-friction. It requires proprietary vendor certification just to move a servo. A game dev used to the fluid, object-oriented, rapid-prototyping environment of Unreal Engine looks at a ladder logic diagram and sees the Stone Age.

We are wasting high-velocity talent on low-velocity infrastructure.

VI. The Universal Physics Kernel

The acceleration of Physical AI depends on one specific breakthrough: The Universal World Model.

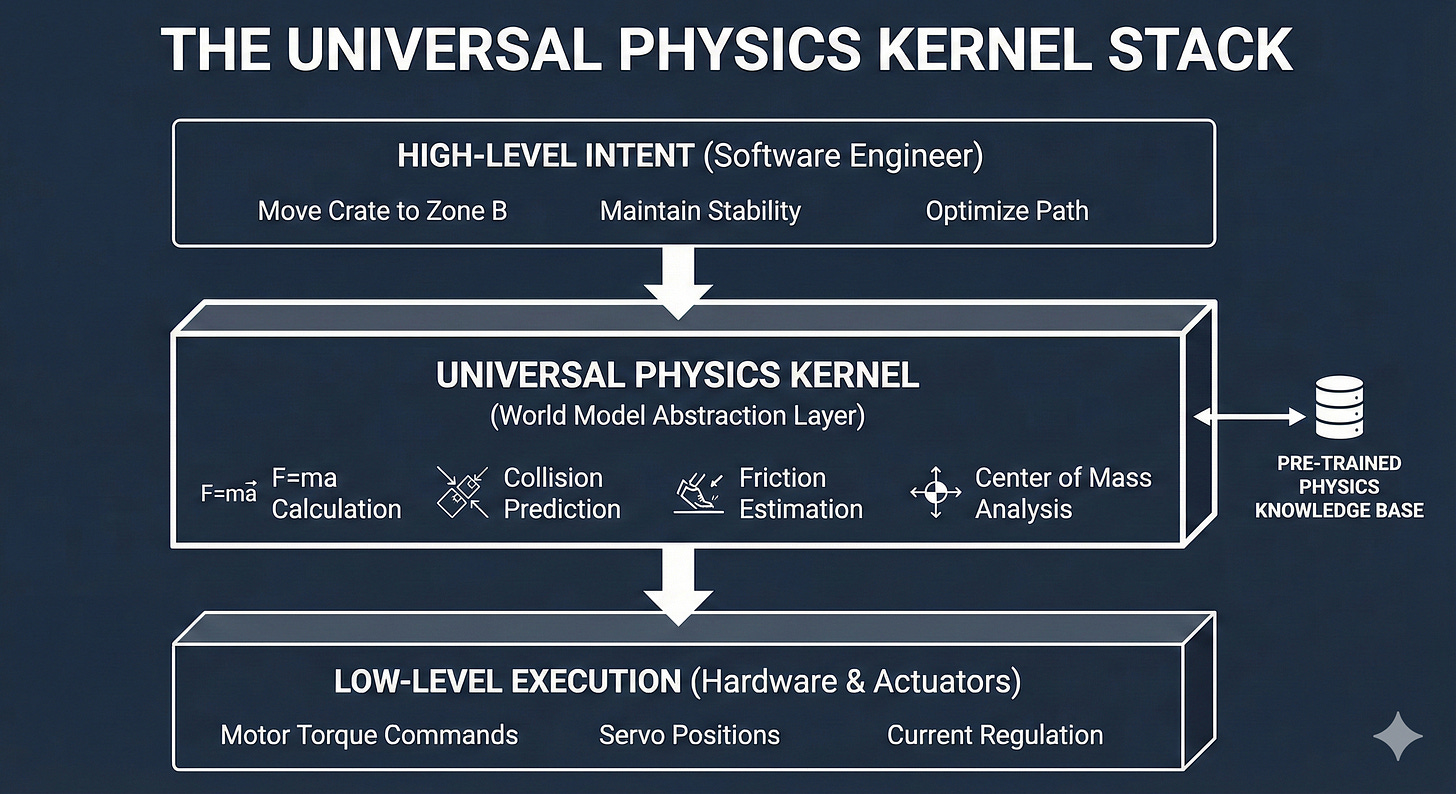

We need an abstraction layer.

In the early days of the internet, you had to manage your own server hardware. You had to worry about the physical spinning disk. Then came AWS. It abstracted the hardware.

In the early days of web dev, you wrote raw TCP/IP sockets. Then came HTTP libraries. It abstracted the networking.

We need the “HTTP for Gravity.”

We need a foundational model—a pre-trained Physics Kernel—that understands the universal laws of interaction. This model would serve as the translation layer between the intent of the software engineer and the reality of the hardware.

Imagine a system where the engineer writes: “Move crate to Zone B, maintain stability.”

The Universal World Model receives this intent. It instantly calculates the center of mass, the friction of the floor, the acceleration curve required to prevent tipping, and the torque limits of the motors. It translates the high-level code into the low-level kinetic execution.

This is the “API for Physics.”

If we build this, the transition speeds up by an order of magnitude. It allows the software engineer to remain a software engineer. They don’t need to learn differential equations; they just need to call the function. The “Physics Gap” is closed not by retraining the human, but by upgrading the system.

This is the ultimate leverage. We stop asking coders to be physicists. We build a system that knows physics, so the coder can focus on the logic.

VII. Systems Over Heroics: The Ultimate Leverage

The core of my operating philosophy is simple: Systems Over Heroics.

The hero saves the day once. The system saves the day forever.

In the physical domain, we have relied on heroes for too long. The truck driver pushing through a 14-hour shift to make a delivery. The factory foreman who intuitively knows how to kick the machine to make it run. The warehouse worker lifting double their capacity to meet a quota.

This is heroic. And it is a failure of system design.

Reliance on human physical exertion to bridge the gaps in our systems is a structural weakness. It is non-scalable. It is fragile. If the hero calls in sick, the system collapses.

Physical AI is the ultimate implementation of “Systems Over Heroics.”

It moves the load-bearing capacity from the biological back to the silicon architecture. It creates a system where the execution of physical tasks is deterministic, not probabilistic.

When you have a World Model that can predict the outcome of an action, you don’t need a hero to improvise. You need a machine to execute.

This shifts the role of the human operator. We are no longer the muscle. We are no longer the nervous system reacting to immediate stimuli.

We become the architects.

We design the parameters of the World Model. We define the constraints of the system. We optimize the loops. We stand outside the cage, not inside it.

The “work” shifts from kinetic effort to systemic design. The scaling happens not by adding more sweating bodies to the line, but by increasing the compute density of the World Model.

We are building a machine that eats entropy for breakfast.

VIII. The End of Drift

In any physical system, drift is the enemy. Mechanical parts wear down. Calibrations slip. Processes degrade over time.

Human attention drifts, too. We get bored. We get complacent. Quality control slips after lunch.

Physical AI offers the promise of Zero Drift.

A system driven by a World Model constantly compares reality to the simulation. It detects the micro-deviations before they become failures. It notices the vibration in the motor shaft before the bearing seizes. It notices the slight inefficiency in the logistics route and corrects it instantly.

It maintains absolute focus. It does not bargain with convenience. It does not cut corners because it is tired.

It possesses the “Subdued Authority” of a law of nature. It just works, relentlessly, quietly, efficiently.

This is the future of the industrial base. Not a noisy revolution of flashing lights and sci-fi promises, but a quiet cementing of reliability.

We are leaving the screen. We are entering the age where our code has mass.